Quality

Delta Automotive Technologies Lobatse places the highest priority on Quality Assurance and has invested heavily in systems, equipment, training and human resources to ensure that we meet the highest global standards.

Delta Lobatse’s aim is to maintain IATF 16949:2016 accreditation, together with the implementation of additional customer-specific requirements, fulfills all current customer requirements. Customer and independent third party verification in the form of product, process and systems verification audits are conducted at regular intervals. This ensures Delta Lobatse’s approval as a global supplier to customers such as Nissan, Renault, VWSA, Iveco, UD Trucks, Grupo Antolin and many more.

In terms of our Quality Management System, quality is the responsibility of each employee to ensure that the necessary controls are implemented and updated by continuous improvements. Each main process owner takes full responsibility for his processes, thus ensuring the highest quality.

To ensure superior quality products Delta Lobatse invests into the most modern technologies in various quality control testing facilities. These facilities include the SBL 1000 quality engineering compact Micrograph Lab that has facilities to conduct:

- Sectioning of terminals

- Grinding and polishing of terminals

- Etching of terminals

The computerised microscope linked to specialised software is used to conduct measurements on terminal crimp height, crimp width and crimp compression ratios, 10 point checks.

This information together with the visual display is valuable input in the approval of terminal crimps, continuous improvement programs, preventative maintenance and on-going process capability studies to ensure quality products are delivered to our customers.

To ensure superior quality products Delta Lobatse invests into the most modern technologies in various quality control testing facilities. These facilities include the SBL 1000 quality engineering compact Micrograph Lab that has facilities to conduct:

- Sectioning of terminals

- Grinding and polishing of terminals

- Etching of terminals

The computerised microscope linked to specialised software is used to conduct measurements on terminal crimp height, crimp width and crimp compression ratios, 10 point checks.

This information together with the visual display is valuable input in the approval of terminal crimps, continuous improvement programs, preventative maintenance and on-going process capability studies to ensure quality products are delivered to our customers.

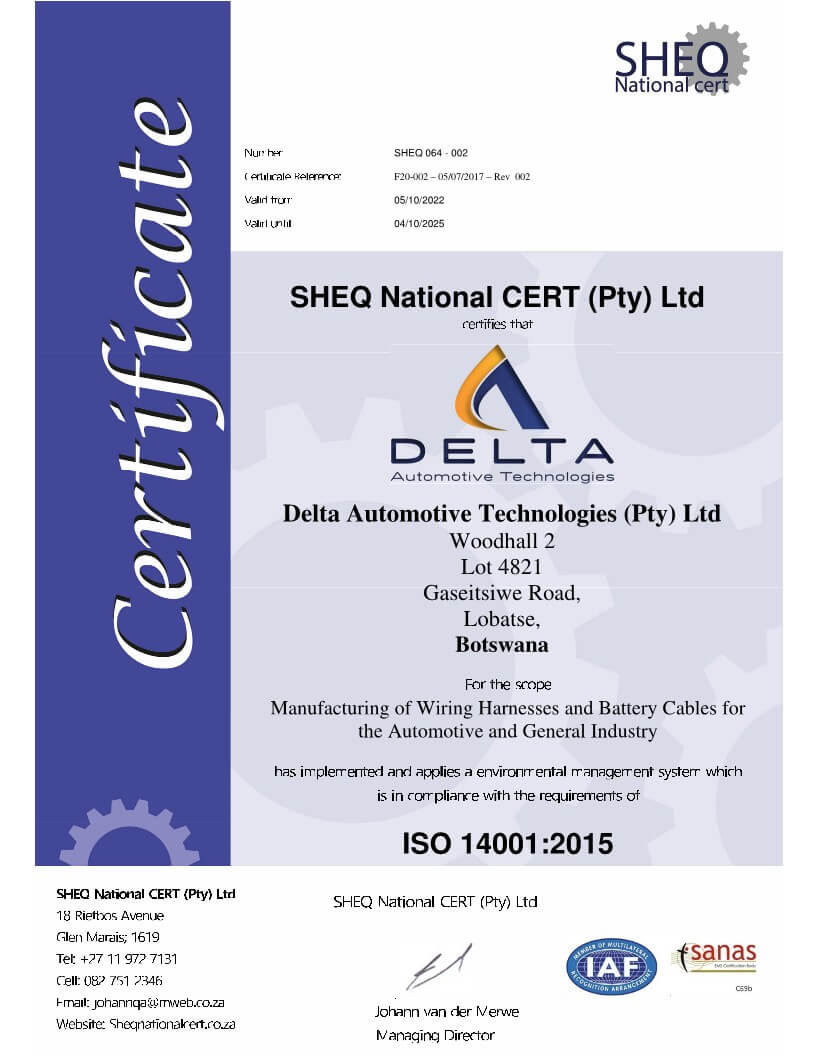

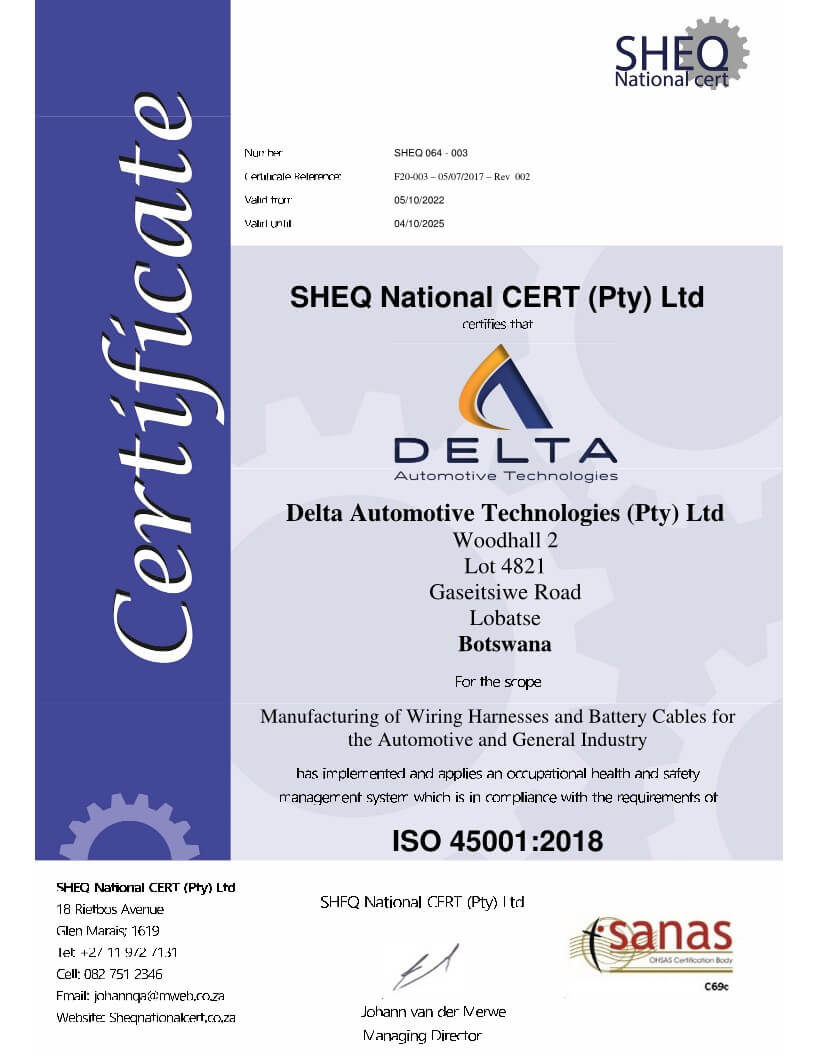

QUALITY CERTIFICATIONS

Contact Us

Tel: +267 533 0950

E-mail: info@datbw.com

Lobatse, Botswana

Postal: PO Box 694, Lobatse, Botswana